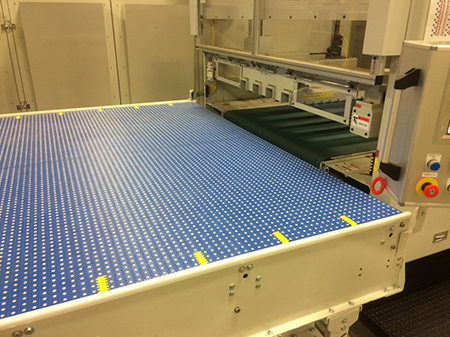

Description

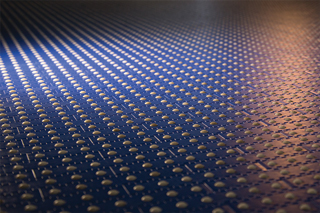

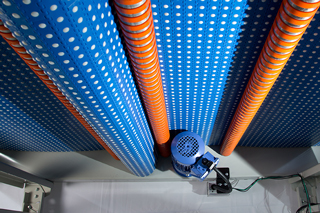

Lateral product movement is achieved by utilizing internally mounted powered belts, which ride under and drive the balls in the Modular Ball-Belt.

Designed to transfer single bundles or accumulate and transfer multiple bundles. With fewer moving parts and no pneumatics, your bundle-building operations will benefit from the low maintenance and high uptime.